- August 5, 2025

- smileytoonzstudio@gmail.com

Introduction

In today’s fast-paced industrial and technological world, precision is everything. Whether you’re manufacturing automotive parts, conducting laboratory research, or ensuring the safety of medical equipment, accurate measurements are crucial. Even the most advanced instruments can lose accuracy over time due to regular use, environmental conditions, or simple wear and tear. This is where calibration comes into play.

Calibration is the process of comparing the measurements of an instrument against a known and traceable standard, identifying any deviations, and making necessary adjustments to restore accuracy. It’s an essential part of quality control and regulatory compliance, helping industries maintain consistent product quality, ensure safety, and avoid costly errors.

In this blog, we’ll explore what calibration is, why it’s important, the step-by-step process, how often it should be done, and the many benefits it offers.

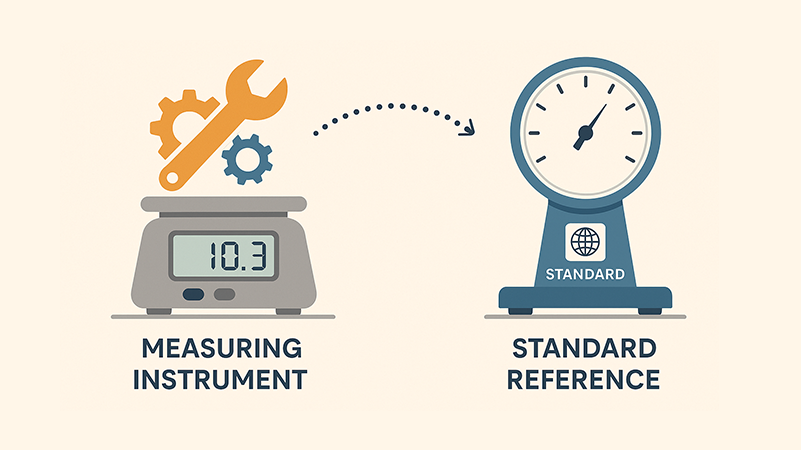

What is Calibration?

Calibration is the process of verifying and adjusting the accuracy of a measuring instrument by comparing its results with a standard reference. This standard is often traceable to a national or international measurement standard, ensuring global consistency.

For example:

- A thermometer can be calibrated by comparing its readings against a certified temperature standard.

- A weighing scale can be checked against known reference weights.

- A pressure gauge can be tested using a calibrated master gauge.

The primary goal is to ensure the instrument provides reliable and accurate results every time it’s used.

Why Calibration is Important

The importance of calibration cannot be overstated. Here’s why it matters:

- Ensures Measurement Accuracy

Inaccurate measurements can lead to defective products, safety hazards, and financial losses. Calibration helps maintain accuracy and reduces errors. - Maintains Compliance

Many industries must adhere to strict standards such as ISO/IEC 17025, ISO 9001, or other regulatory requirements. Regular calibration ensures compliance with these standards. - Avoids Costly Mistakes

An uncalibrated instrument can produce incorrect data, leading to faulty products, customer complaints, or even recalls—each of which can be expensive and damaging to a brand. - Builds Trust

Whether it’s a customer, regulatory body, or quality auditor, knowing that instruments are regularly calibrated improves confidence in your processes.

The Calibration Process

Calibration is a systematic and well-documented process. While the exact steps may vary depending on the instrument and industry, here’s a general outline:

- Selection of Reference Standard

- Choose a highly accurate, certified reference instrument or standard that is traceable to national or international measurement standards.

- Comparison of Measurements

- Test the instrument under calibration by comparing its readings against the reference standard at various measurement points.

- Adjustment (If Necessary)

- If deviations are found, make adjustments to bring the instrument back within acceptable limits.

- Re-testing

- After adjustments, re-check the instrument to confirm it meets the required accuracy.

- Documentation and Certification

- Record the calibration results, adjustments made, and the date of calibration. Provide a calibration certificate for traceability and compliance.

Types of Calibration

Different instruments require different calibration methods, including:

- Mechanical Calibration – For devices measuring force, torque, mass, etc.

- Electrical Calibration – For voltmeters, ammeters, oscilloscopes, etc.

- Dimensional Calibration – For tools like calipers, micrometers, and gauges.

- Thermal Calibration – For temperature sensors, thermometers, and thermostats.

- Pressure Calibration – For pressure gauges, transmitters, and barometers.

How Often Should Calibration Be Done?

The frequency of calibration depends on several factors:

- Manufacturer’s Recommendation

Most equipment comes with a suggested calibration interval. - Usage Intensity

Instruments used frequently or under harsh conditions may require more frequent calibration. - Industry Standards

Some industries, like healthcare or aerospace, have strict calibration schedules. - Criticality of Measurement

If a measurement directly impacts safety or quality, more frequent calibration is essential.

As a general rule, annual calibration is recommended, but critical equipment may need it quarterly or even monthly.

Benefits of Regular Calibration

Regular calibration offers multiple benefits beyond just accuracy:

- Improved Product Quality

Consistent and accurate measurements lead to better product quality and customer satisfaction. - Regulatory Compliance

Meeting ISO or industry-specific standards ensures smooth audits and certifications. - Operational Efficiency

Reduces downtime caused by faulty equipment and avoids rework due to inaccurate measurements. - Cost Savings

Prevents expensive product recalls, production stoppages, and warranty claims. - Extended Equipment Life

Early detection of performance issues can help maintain equipment and extend its usable life.

Choosing the Right Calibration Service Provider

Not all calibration services are created equal. Here’s what to look for:

- Accreditation

Choose a provider accredited to ISO/IEC 17025 or other recognized standards. - Experience and Expertise

Look for companies with proven experience in your specific industry. - Modern Facilities and Equipment

Ensure they use the latest technology and maintain strict quality controls. - Turnaround Time

Downtime can be costly, so pick a provider that offers quick yet reliable service. - Detailed Documentation

A good provider will give you a comprehensive calibration certificate with traceability details.

Conclusion

Calibration is not just a technical necessity—it’s a cornerstone of quality, safety, and reliability in every industry. From manufacturing to healthcare, accurate measurements ensure that processes run smoothly, products meet quality standards, and safety is never compromised.

By making calibration a regular part of your maintenance schedule, you protect your business from costly errors, maintain compliance, and enhance customer trust. Whether you manage a production line, run a laboratory, or maintain critical safety equipment, partnering with a certified calibration service provider is one of the smartest investments you can make.

At NCS – National Calibration Service, we pride ourselves on delivering precise, reliable, and ISO-certified calibration services. With modern facilities, experienced professionals, and a commitment to excellence, we ensure your instruments meet the highest accuracy standards.

For more details follow our Instagram & Facebook page.

Choose NCS for your calibration needs — because precision is our promise.